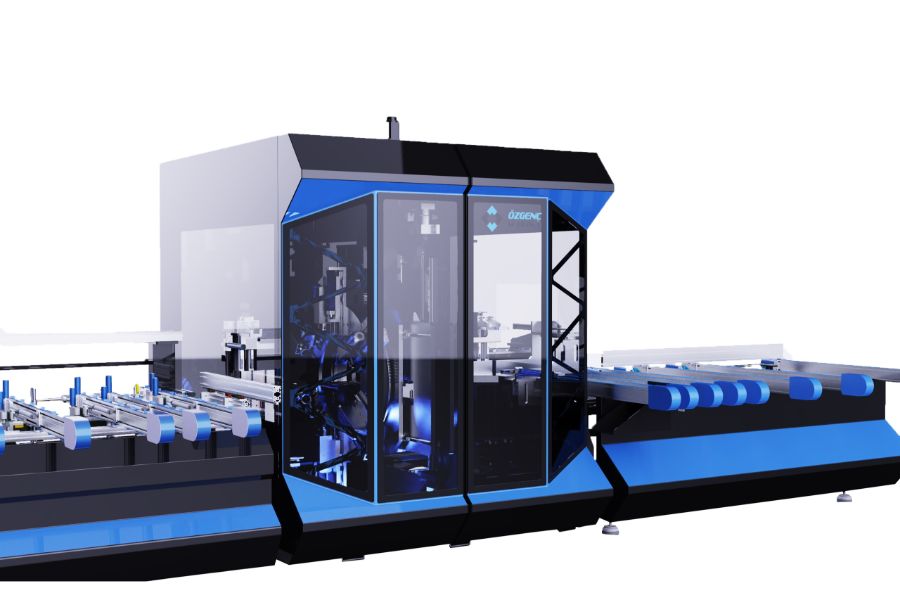

Доставка, монтаж и въвеждане в експлоатация на Четириглава залепваща и CNC зачистваща производствена линия за ПВЦ прозорци и врати OZGENC TURBOWELD 400. Повече за това оборудване може да видите ТУК

Оzgenc MRT 300

Махтек еоод

МАХТЕК ЕООД е една от водещите фирми на Българския пазар за доставка, монтаж и поддръжка на машини за производство на прозорци, врати, фасади и други. Фирмата е официален представител на производителите OZGENC MAKINA, Ozcelik и MachTec. - едни от водещите производители, специализирани в производството на машини, нужни за изработка на ПВЦ и алуминиеви прозорци и врати. Освен продажба, фирмата предлага гаранционен и извънгаранционен сервиз. Професионализма на нашите техници позволява поддръжка и на машини, които не са доставени от нас.

Новини

Инсталация и въвеждане в експлоатация на CNC Рутер 2136 PRO

Инсталация и пускане в експлоатация на CNC Рутер с работни размери 2100 х 3700 мм. и допълнително въздушно охлаждане на работната зона. Подходящ, както за МДФ, така и за композитни панели (бонд), HPL, алуминиеви плочи и друг листов материал. Повече информация за машината ТУК