ozgenc MRT 1967

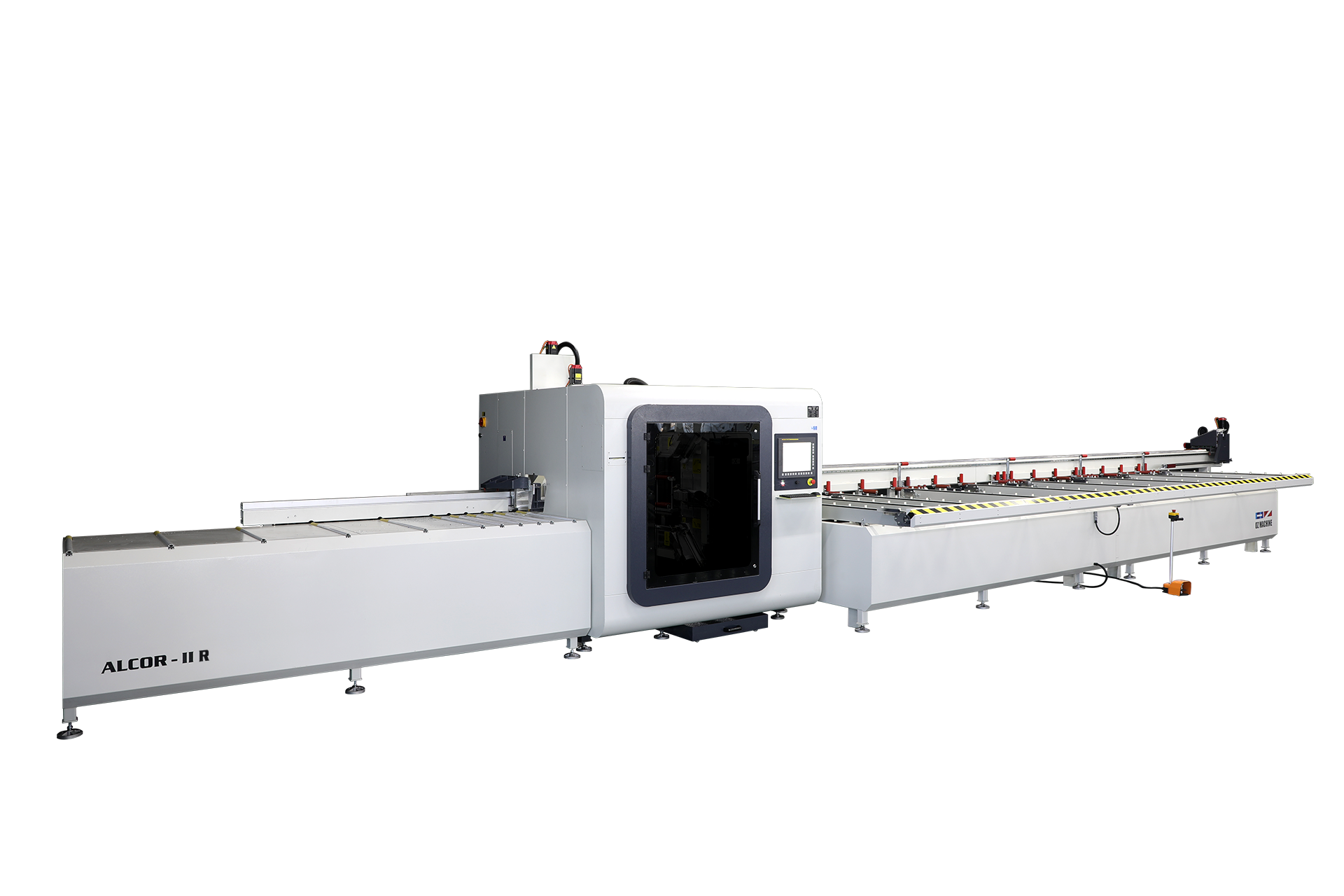

Aluminium Profile Cutting and Machining Center

Send an inquiryImage gallery

Watch video

Download specifications

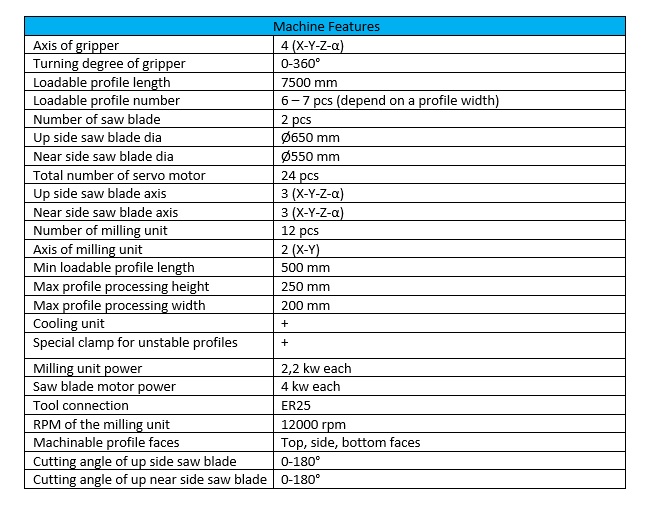

Technical specifications

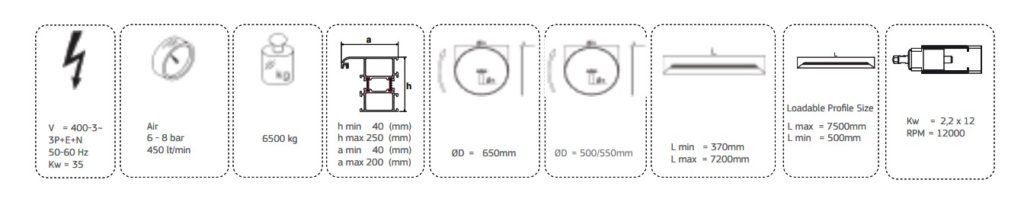

MRT 1967 aluminium profile cutting and processing center can do all operations on four sides of aluminium profiles.

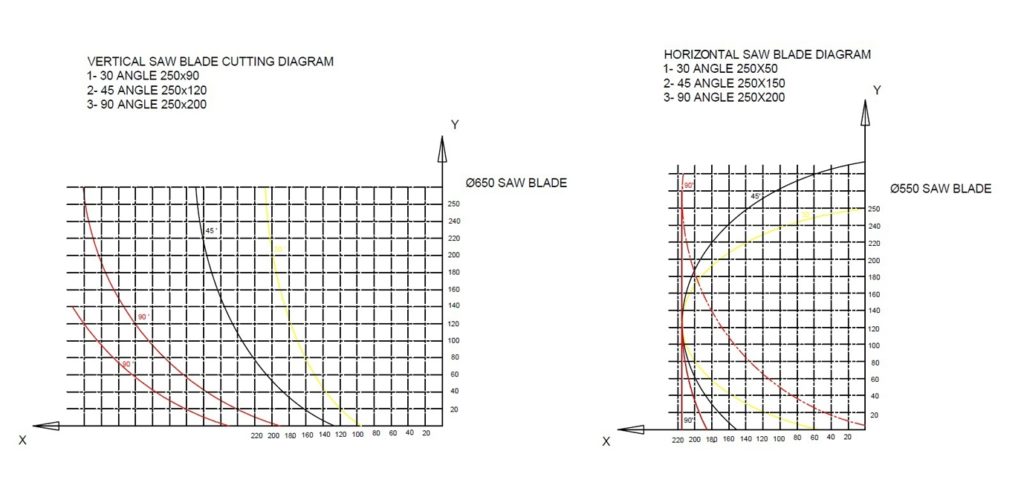

- 12 high-speed custom-made and air-cooled spindles are able to cut for all angles from 0° to 180° with 0.1° precision, by means of a servo axis-controlled.

- Standard Cutting Operations + V Cutting + 90 Degree Notch + Coumpound Angle Notch operations(Standard operations : Horizontal Line Operation, Single Hole Operation, Circle Operation, Rectangular Operation, Horizontal Capsule Operation , Cylinder Operation

- Vertical Capsule, Head Upright Cylinder Operation, Head Downright Cylinder Operation, Vertical Line,Rectangle Milling Operation)

- 1x 650 mm and 1x 550 mm diameter saw.

- 3 axes and 360 rotatable gripper positioning.

- Automatic positioning clamps unit

- Automatic profile length recognition.

- Ability to load profiles in any size from 500 mm to 7500 mm for profile feeding unit.

- Equipped with an automatic lubrication system.

- A profile conveyor system with high precision.

- Remote Access.

- Vertical alignment system.

- Special milling tools for processing aluminium.

- Each clamps can adjust the pressure system.

How can we help?

We offer warranty and post-warranty service on all machines of this type.

Got questions? Do not hesitate to contact us. We will visit your facility and find the right solution for your needs.

Similar Products

Send an Inquiry for ozgenc MRT 1967