Designed for welding corners of PVC profiles.

-Full automatic control

-Maximum durability of a welding seam

-Welding corner is regulated from 25 ° to 180 ° degrees

-Serial compression of the upper cylinders

-Special blades for limitation welding seal (welding seal thickness from 2 mm. to 0,2 mm.)

-Adjustable supporting arms for profiles

-Easy and practical control of the machine by pedal

-PLC control system

-Heating element has the thermostatic control

-Output of heating element temperature on display

-Adjustment of heating temperature, welding time and pressure for different kinds of profile

-Quick-detachable system of molds saves time at their replacement Reset function allows to cancel the executed step of profile pressure at its incorrect installation, that essentially saves time in comparison with an emergency stop

-Particular care has been taken over the safety measures, both mechanical and electrical

-Power supply protects system from voltage overload

Technicial Specifications

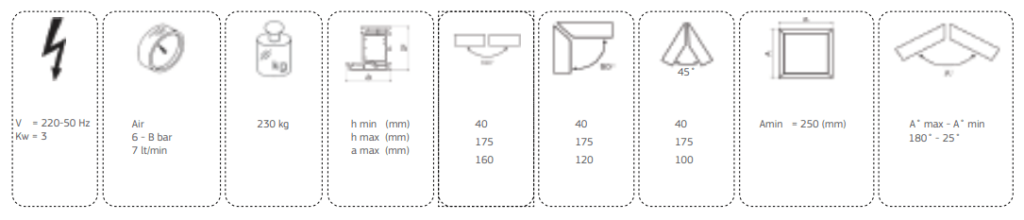

-Power Supply : 220 V, 1 ph, 50-60 Hz

-Motor kW : 1,5 kW

-Air Consumption : 7 lt/min

-Air pressure : 6-8 bar

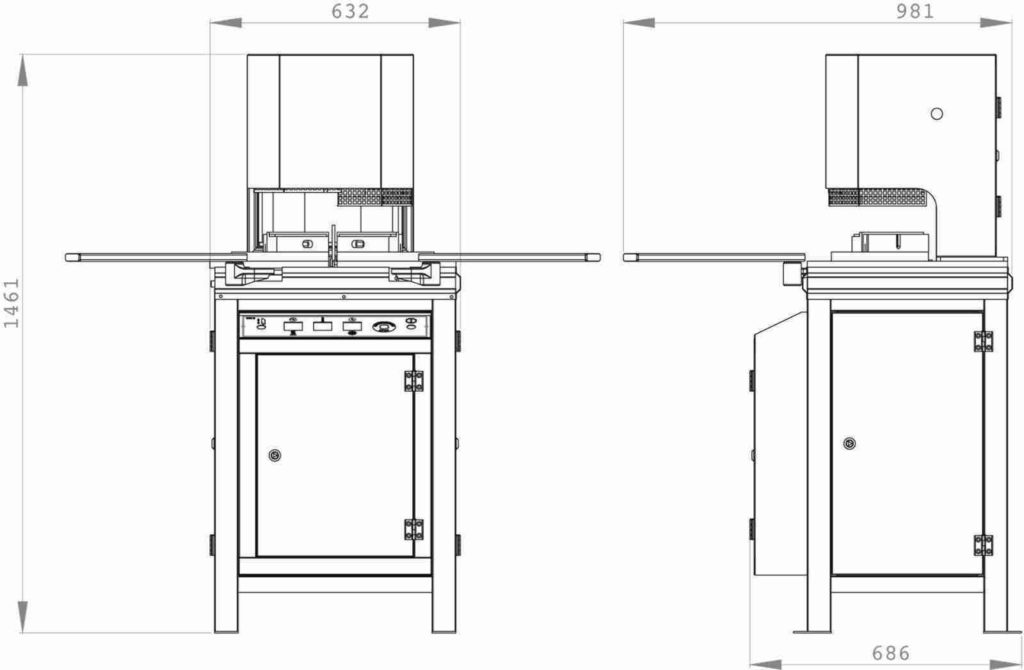

-Machine Height : 1470 mm

-Machine Length : 1350 mm

-Machine Width : 990 mm

-Machine Weight : 230 Kg

-Minimum Boostable Profile Height : 45 mm (180 deg), 45 mm (90 deg), 45 mm (45 deg)

-Maximum Boostable Profile Height : 175 mm (180 deg), 175 mm (90 deg), 175 mm (45 deg)

-Maximum Boostable Profile Width : 198 mm (180 deg), 158 mm (90 deg), 98 mm (45 deg)

-Boostable Frame Minimum Width and Length : 250*250 mm

-Boostable Frame Maximum Width and Length : 0

-Can Work Angle Range : Min: 250 Max: 1800