Designed to clean the corners of PVC profiles from welding seals.

-Used to clean the welded corners of PVC windows

-CNC control system (2 axis)

-Corner cleaning time 15-25 sec. depending on profile type

-Movable 8.4” touch screen panel

-Easy system for profile setup and programming

-High cleaning performance with tools operated by servo control

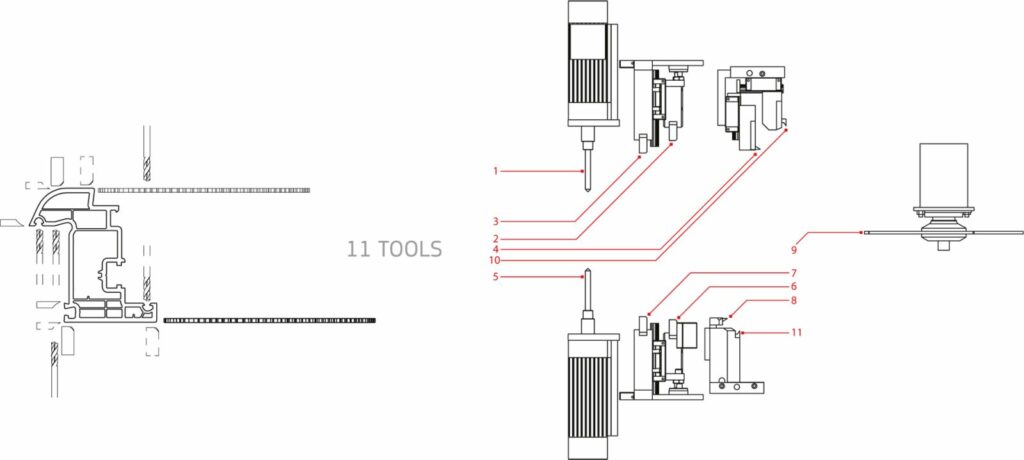

-High and standard quality in each profile surface with 9 cleaning tools

-Up & bottom gasket hole drills

-Up & bottom inner corner cleaning system (special patented design)

-Up & bottom color – white surface cleaning blade system

-Separate blades for white and laminated profiles

-Adjustment of operating speeds to the desired speeds

-Wide stand with brushes provides easy operation and protects profile surface from scratches

-500 profile memory capacity

-Multi language support

-Shift processing capacity: 190 – 200 items / 8 hours

Technicial Specifications

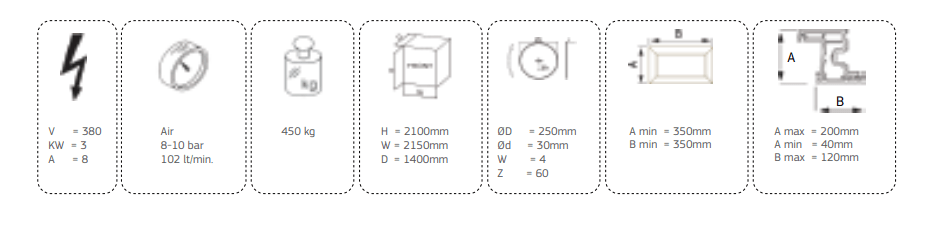

-Power Supply : 380-400 V, 3 ph, 50-60 Hz

-Spindle speed : 2800 rpm

-Total Power : 3 kW, 8A

-Motor kW : 1,5 kW

-Air Consumption : 102 lt/min

-Air pressure : 6-8 bar

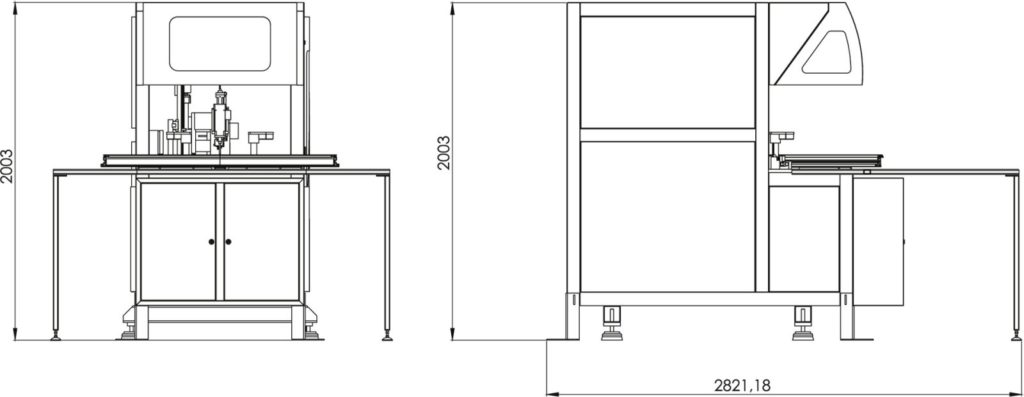

-Machine Height : 2050 mm

-Machine Length : 1900 mm

-Machine Width : 1050 mm

-Machine Weight : 450 Kg

-Saw Outside Diameter : Ø250

-Inside Diameter of Saw : Ø30

-Saw Thickness : 4-4,3 mm

-Number of Teeth : 60

-Maximum Machinable Profile Height : 200 mm

-Minimum Machinable Profile Height : 40 mm

-Maximum Machinable Profile Width : 120 mm